- Overview

- Recommended Products

Product Details

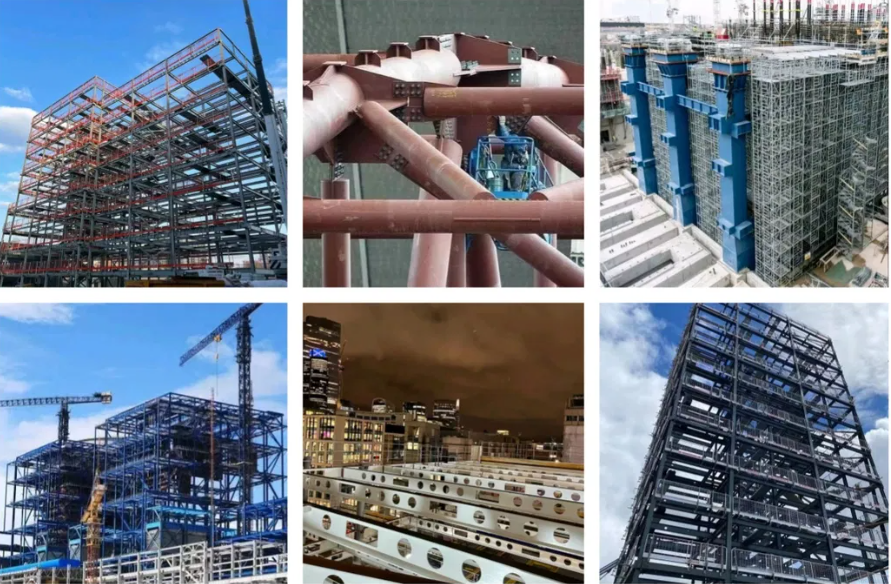

1. High strength: steel strength is high, can withstand large loads, suitable for large span and high-rise buildings.

2. Light weight: compared with concrete, steel structure light weight, reduce the foundation burden, reduce the foundation cost

3. Prefabrication: steel components can be prefabricated in the factory, on-site installation, shorten the construction period.

All-weather construction: little affected by weather, high construction efficiency

Large span: high steel strength, suitable for large space design, such as exhibition halls, stadiums, etc.

Easy transformation: easy to expand or transform later, to adapt to functional changes.

4. Good seismic performance

High toughness: steel ductility is good, can absorb seismic energy, seismic performance is better than concrete structure.

5. Environmental protection and sustainability

Recyclable: Steel can be recycled to reduce construction waste.

Energy saving: Low energy consumption during construction, reduce environmental pollution

Description:

EN 1090 is the implementation standard for steel structures, CE certification is required, as well as material standards such as EN 10025, welding standard ISO 3834, corrosion protection standard EN ISO 12944

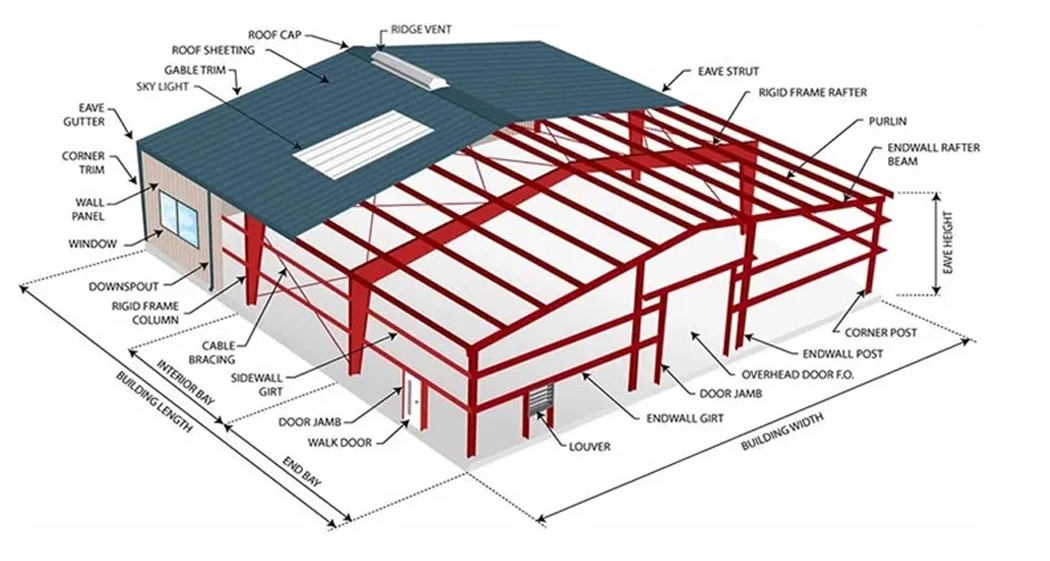

Main Materials for Steel Structure Consturction

| Item | Materials | Remark |

| SteelFrame | H section column andbeam | Q345 steel, paint or galvanization |

| wind resistant column | Q345 steel, paint or galvanization | |

| Secondarybracing | Roof purin | Q235B C/Z section galvanized steel |

| Wall purin | Q235B C/Z section galvanized steel | |

| Tie bar | Q235,φ89'3 round steel pipe | |

| knee brace | angle steel,Q235,L50°4 | |

| roof horizontal bracing | φ20,Q235B steel bar, paint or galvanized | |

| column vertical bracing | Φ20,Q235B steel bar, paint or galvanized | |

| casing pipe | φ32*2.0,Q235 steel pipe | |

| Pulling bar | Φ10 round bar Q235 | |

| Roof and wallprotecting system | Wall and roof panel | corrugated steel sheet/sandwich panel |

| gutter | color steel sheet/galvanized steel/stainless steel | |

| Trim and flashing | color steel sheet | |

| downspout | PVC | |

| self tapping screw | ||

| Fastener system | Anchor bolts | Q235 steel |

| High strength bolt | The Specifications shall be determined according to the design of steel structure. | |

| Normal bolt | ||

| Nuts | ||

| Window and door | Window | Aluminium windows |

| Door | According to requirement to choose, can be EPS door, windproof door, high-speed roll-up door, industrial sliding door etc. |

Applications:

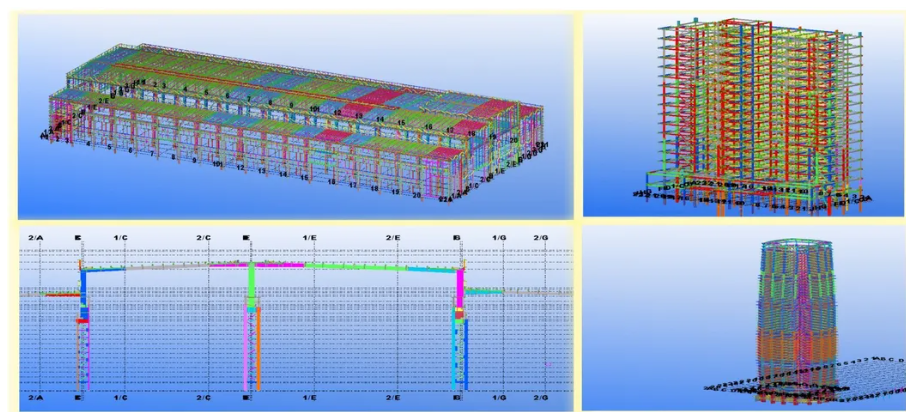

The main products set steel structure, grid, curtain wall and light roof design, research and development, production, construction and installation and technical services in one. It owns PKPM, 3D3S, Shanghai Waigaoqiao, MST, MIDAS, STAAD. Such design software, advanced complete sets of CNC processing and manufacturing equipment, rich experience in steel structure, grid, curtain wall and light roof construction.

Advantages:

1. Having us is equivalent to having a strong design team, rigorous processing quality, enthusiastic after-sales service, professional technical guidance. You only need to place an order and we can serve you from the beginning to the end of the project.

2. Our company has more than 70,000 square meters of modern production plant, steel structure production line 10, enclosure system production line 9, grid production line 5, pipe truss production line 4, enclosure system production line complete, with more than 3,000 square meters of R & D base, test and testing center, the company's annual steel structure production and processing capacity of more than 100,000 tons. There are more than intermediate professional title and above technical personnel, with more than 20 national patents, trademark registration rights 2. Escort your products.

3. Customized design: according to customer requirements, for you to design satisfactory products.

Delivery: The factory is close to the port of Qingdao, about 300 kilometers, the company is equipped with logistics department, and a number of year-round cooperation with freight forwarding companies, transport costs are extremely low.

FAQ:

International certification: In line with EN 1090, ISO 9001, European standard CE certification high level standards, to ensure universal.

It would be better if you could supply us the following parameter before we design the drawings for you:

1 Location (where will be built)? _____country, area

2 Size: length*width*height? _____m*_____m*_____m

3 Wind load (or max. wind speed)? _____km/h

4 Rain & snow load (or max. snow height)? _____kn/m2, _____mm

5 Anti-earthquake _____level ?

6 Usage of the building?

7 Roof panel and wall panel? You could choose the sandwich panel, EPS, fibreglass wool, rock wool, PU sandwich. You could choose corrugated steel sheet and glass wool installed together on site either.

8 Brick walls needed or not? If yes, 1.2m high or 1.5m high? If yes, 1.2m high or 1.5m high?

Q4: What kind of building drawings will the factory provide?

A: Plan, elevation, section, foundation, installation.

Q5: What drawing of a house will factory supply?

A: Plan drawing, elevation drawing, sectional drawing, foundation drawing, installation drawing.

Q6: How many types of sandwich panel do you have?

A: We have EPS(polystyrene)sandwich panel, rock wool sandwich panel, and PU(polyurethane)sandwich panel.

The characteristics of your sandwich panels respectively:

1. EPS(polystyrene)sandwich panel: Thickness is 50mm, 75mm, 100mm. EPS volume weight is 80-200Kg/m3, water-proof.

2. Rock wool sandwich panel: Thickness is 50mm, 75mm, 100mm. Rock wool volume weight is 200-400Kg /m3, fire-proof, sound-insulation, heat-preservation.

3. PU(polyurethane)sandwich panel: Thickness is 50mm, 75mm, 100mm. PU volume weight is 150-300/m3 water-proof, fire-proof, heat-proof, heat-insulation, heat-preservation, sound-insulation.